What we do

Eurostampi relies on employees with many years of experience in the construction of plastic moulds. The entire team is encouraged to find the most appropriate solutions to obtain a final thermoplastic mould corresponding to customer requirements with the various departments working in perfect synchronisation to ensure maximum efficiency of the entire production process.

Plastic product design

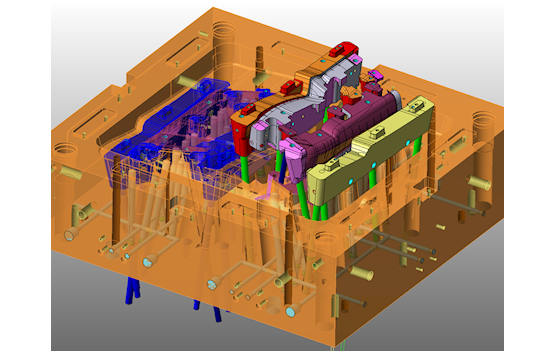

The company's in-house technical department works closely with the customer in order to find technical solutions able to guarantee a finished product of high quality and utmost reliability. Starting from the mathematical model or drawing, technicians quickly and accurately develop the mould design using CAD/CAM systems.

Design is based on the use of two-dimensional (2D) and three-dimensional (3D) CAD applications. The main software products used are VISI and WORKnc which are constantly updated. The data exchanged with customers can be read in various formats: step, iges, dxf, catia, dwg, catpart.

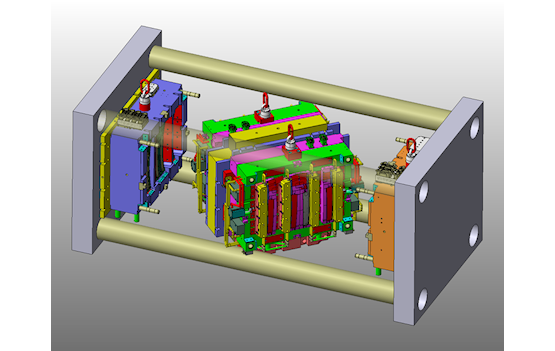

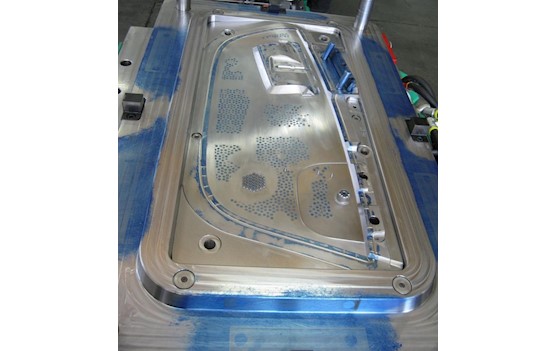

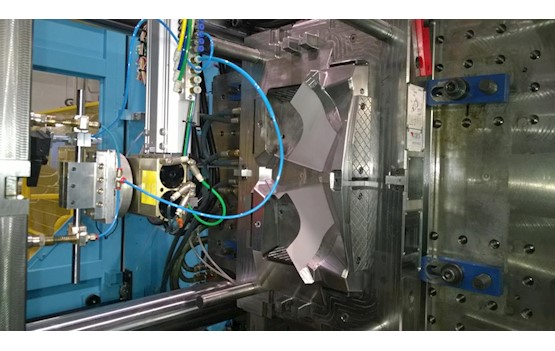

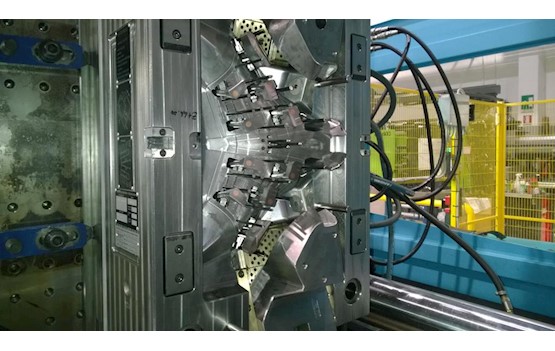

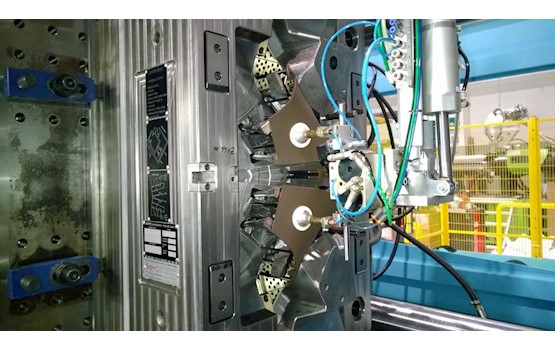

Thermoplastic mould construction

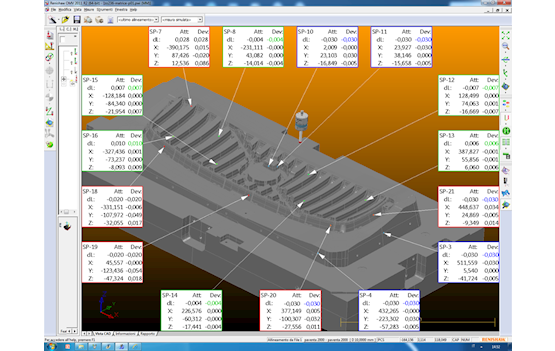

The production department carries out all the machining and activities necessary to create the mould, from roughing to finishing with from 3 to 7 axis machine tools and stroke up to 2500 x 1800 x 1100 mm. During machining, various dimensional verification steps are envisaged on the parts under construction. The adjustment department assembles the various components, performs the necessary adaptations and completes the mould with the agreed surface finishes.

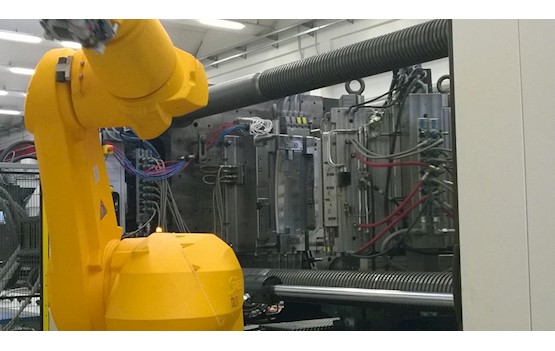

External mould testing

Completing the in-house activities, before delivery to the customer and the subsequent production start-up, the mould is subjected to final testing to ensure its correct functionality and full efficiency. To perform mould testing the company makes recourse to trusted external suppliers with small, medium and large tonnage presses.

Thermoplastic Mould Maintenance

The company provides both a routine as well as extraordinary mould maintenance service and carries out adjustments and modifications to ensure the usual quality.

Addtional Services

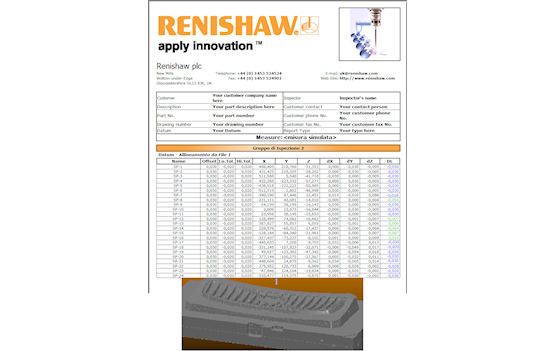

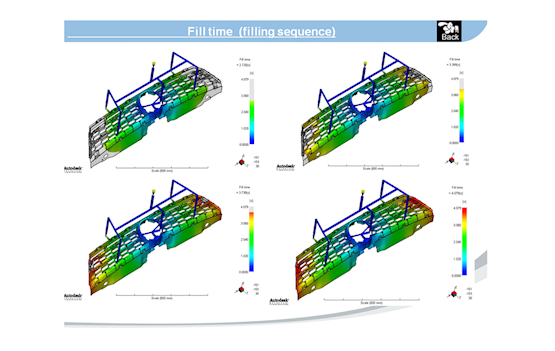

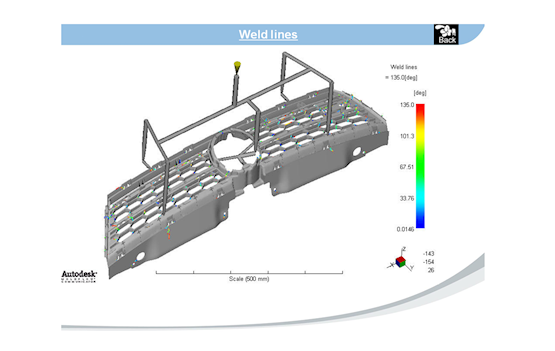

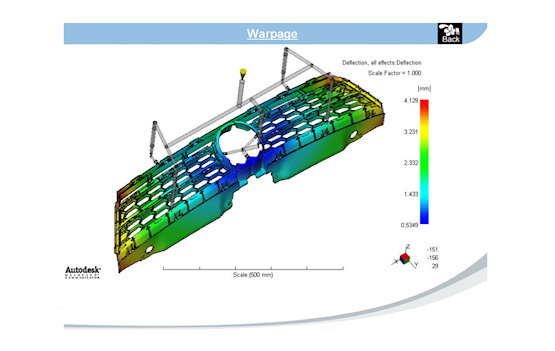

At the customer's request, feasibility studies are carried out to evaluate the implementation and developmental issues of a new product. Mould flow analyses are carried out to verify filling, deformation and cooling in order to evaluate each injection phase and to provide a product that meets the required standards. Relying on external suppliers, dimensional checks on the moulded part are carried out, providing the related dimensional reports on its forms or those of the customer.