Plastic product design

Starting from the mathematical model or drawing, technicians quickly and accurately develop the plastic mould design using CAD/CAM systems.

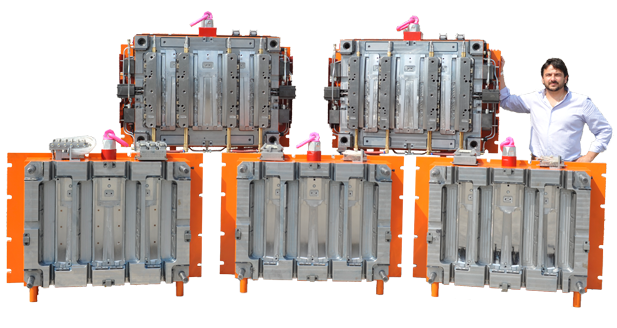

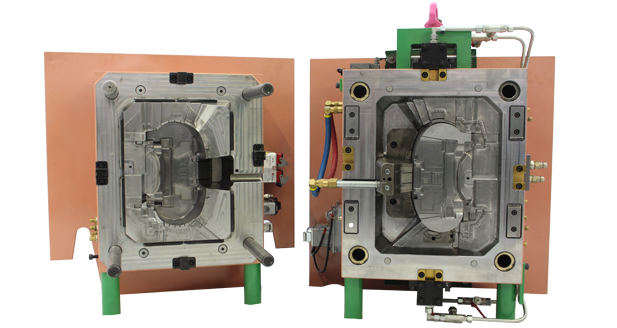

Plastic mould construction

Not only design but also implementation of all activities and processing for construction of the mould for plastics

External thermoplastic mould testing

Before delivery to the customer and the subsequent production start-up, the mould for plastics is subjected to final testing to ensure its correct functionality and full efficiency.

Welcome to Eurostampi

The design and construction of thermoplastic moulds immediately specialised in supplying products to the automotive industry.

Choice that has allowed it to acquire significant experience and solid expertise in this industry that customers distinctly recognise and that have allowed Eurostampi to consolidate its position.

Over the years, depending on market opportunities, Eurostampi has acquired the software and equipment instrumental to customer needs and harnessed the new technologies necessary to meet the current qualitative and aesthetic requirements.

In 2019, the important milestone of 30 years of activity was reached, made possible also thanks to customers who, over the years, have put their trust in us, allowing the company to grow and improve.

Pierangelo Gardenal

FounderThe company is managed by its founder, Pierangelo Gardenal, who has provided it with all his experience and technical and organisational skills to satisfy customers with a with high quality end product.

Focus on customer needs, professional and motivated employees who share the objectives, open mindedness towards market requirements, as well as creative and alternative thinking are the foundations to successfully meet the daily challenges.

We build thermoplastic moulds for

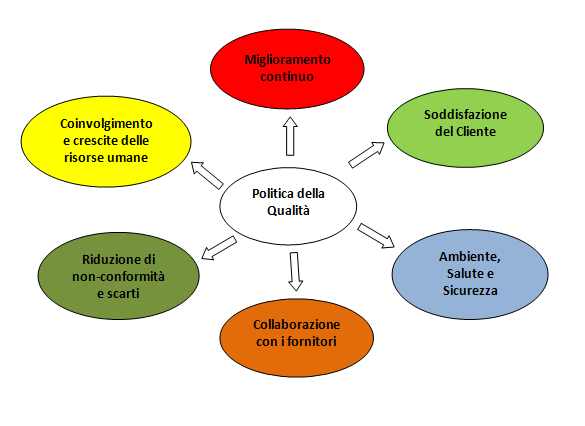

Quality Policy

Eurostampi promotes the quality culture through the dedication of every subject who works in and for the company. Thus, everyone is aware of his role and responsibility in order to achieve the company quality goals and its continuous improvement, even actively collaborating with each other.

“The complete customer satisfaction, based on his evident or implicit needs and expectations, is achieved thanks to everybody's participation in order to grant the products' and given services' quality".

This is realized through the methodical application of the instruments planned by the Quality System according to the requirements exposed in the regulation UNI EN ISO 9001:2015, in order to be considered by the customers as a partner who improves his working quality and follows his emerging needs.

The company's organization and functioning are based on well-defined processes, realized in a systematic, organized and documented way:

Human Resources' Involvement and Development

Man is in the first place, especially his participation and responsibility. He's aware of which his areas of competence are and where to focus his efforts and time. Team work and staff involvement in every level is encouraged by the Management and has to be applied in every working level with Quality goals sharing through education, training, monitoring and effective communication.

Continuous Improvement

- we optimize the productive processes through the constant investment on resources.

- we keep high the products' competitiveness and an excellent price-quality ratio with continuous adjustment of productive capacity and flexibility.

Customer Satisfaction

- we control the level of customer Satisfaction in order to improve the perceived Quality, prevent complaints and respect the contractual delivery terms and the high requested product/service quality.

Non-conformity Reduction

- we optimize costs and minimize the wastefulness.

- we remove product non-conformities through controls in each work phase in order to avoid flaws and minimize waste.

Collaboration with suppliers

- we verify and evaluate the Quality of products' and services' supplies.

- we promote collaboration to grant an overall and wide company Quality (internal and external).